Ribeach nascáil ribeach Ceirmeach Le haghaidh pacáistiú leathsheoltóra

Feidhmchlár táirge

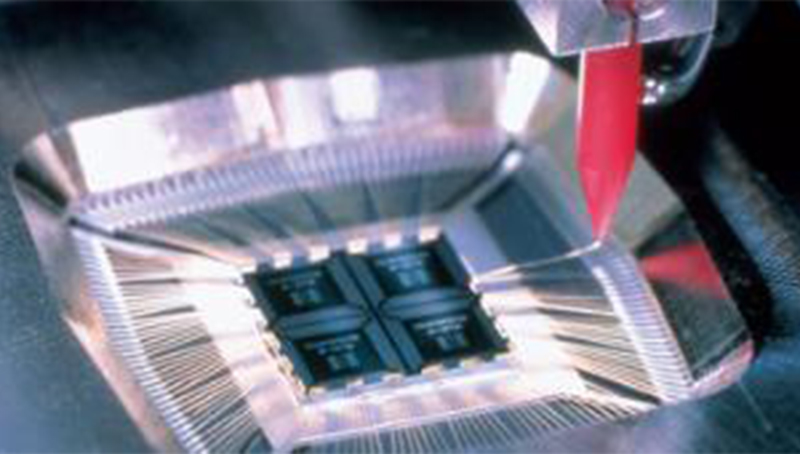

Is uirlis ceirmeach aisimiméadrach é Ceirmeach Capillary le poill sa treo ingearach, a bhaineann le comhpháirt ceirmeach micrea-struchtúr cruinn.I dtéarmaí iarratais, úsáidtear an ribeach ceirmeach mar uirlis nascáil sreang sa phróiseas nascáil sreang.Is féidir le WireBonding an luaidhe miotail a tháthú go dlúth leis an eochaircheap tsubstráit trí úsáid a bhaint as sreanga miotail tanaí (copar, ór, etc.) agus teas, brú, agus fuinneamh ultrasonaic, chun an t-idirnascadh leictreach idir sliseanna agus foshraitheanna a bhaint amach agus an malartú faisnéise idir sceallóga.Oiriúnach do nascáil agus pacáistiú SCR, SAW, stiúir, dé-óid, tríóid, sliseanna IC agus ciorcaid eile.

Buntáistí táirge

OPT Gearradh Uirlisí Co, TEO.lonnaithe i Shenzhen, Guangdong, an tSín.Is cuideachta í a chomhtháthaíonn táirgeadh, díolachán, taighde agus forbairt.Agus is féidir tabhairt faoi dhearadh agus as monarú líníochtaí, ábhar agus uirlisí neamhchaighdeánacha.Glacadh go daingean le hábhair táirgthe intíre den chéad líne chun cobhsaíocht baisceanna éagsúla ábhar a chinntiú.Rialú go docht ar an bpróiseas táirgthe chun cáilíocht na n-uirlisí a chinntiú.Tá fórsa teicniúil nach beag ag an gcuideachta, cumas táirgthe láidir, bainistíocht eolaíoch, leis an gcuspóir "marthanas de réir cáilíochta, forbairt de réir clú", agus dul chun cinn i gcónaí chun táirgí níos fearr a sholáthar do chustaiméirí.

Seachadadh cruinn, seirbhís mhaith

1. Tá a chóras táirgeachta, déantúsaíochta agus iompair iomlán féin ag OPT Cutting Tools.Ar sheachadadh in am.

2. Is féidir cumarsáid agus malartú duine le duine a dhéanamh le custaiméirí chun uirlisí nascáil Ceirmeacha níos oiriúnaí agus níos fearr a sholáthar do chustaiméirí

3. Paraiméadair speisialta a shaincheapadh de réir riachtanais speisialta an chustaiméara;

Nascáil Ábhar Ribeach uasghrádú

Ar bhonn an ocsaíd alúmanaim bunaidh, cuirtear zirconia, ocsaíd cróimiam, etc., chun struchtúr móilíneach an ribeach Ceirmeach a dhéanamh níos dlúithe, le cruas níos airde, friotaíocht caitheamh níos fearr agus saol seirbhíse níos faide.Laghdaigh amanna caitheamh agus athsholáthair tip cliste ceirmeach le linn táthú sreinge.

Ard-chruinneas, cruinneas ard-tríthoiseach, níos lú meaisínithe agus dromchla réidh.

Tá cruinneas ard, cruinneas ardtoiseach ag an táirge, níos lú méid meaisínithe agus dromchla réidh.

Tá struchtúr an Capillary Ceirmeach an-beacht agus casta, agus tá tionchar mór ag a phríomhthoisí ar an éifeacht nascáil sreang.Déanann OPT Cutting Tools rialú docht ar an bpróiseas táirgthe chun cáilíocht na n-uirlisí a chinntiú.Chun cruinneas ard táirge a bhaint amach, cruinneas ard-tríthoiseach, níos lú meaisínithe, agus dromchla réidh.Tá ár gcuideachta tiomanta do T&F agus táirgeadh uirlisí nasctha ceirmeacha baile meánmhéide agus ardghrád i réimse an phacáistithe IC.Déantar páirteanna púdar ceirmeacha agus embryo a fhorbairt agus a tháirgeadh go hiomlán go neamhspleách.

![]()

BPP: 150μm (μm/m)

| Cuid UIMH. | WD | H | T | CD | OR | α | Θ | CA |

| A-1 | 38/1.5 | 51/2.0 | 229/9.0 | 102/4.0 | 38/1.5 | 8° | 30° | 120° |

| A-2 | 38/1.5 | 51/2.0 | 152/6.0 | 66/2.6 | 10/0.4 | 0° | 30° | 90° |

| A-3 | 38/1.5 | 51/2.0 | 229/9.0 | 86/3.4 | 102/4.0 | 0° | 30° | 90° |

| A-4 | 38/1.5 | 51/2.0 | 203/8.0 | 86/3.4 | 61/2.4 | 0° | 30° | 90′ |

| A-5 | 38/1.5 | 56/2.2 | 239/9.4 | 102/4.0 | 38/1.5 | 8° | 30° | 120° |

| A-6 | 38/1.5 | 56/2.2 | 229/9.0 | 96/3.8 | 102/4.0 | 0° | 30° | 90° |

| A-7 | 38/1.5 | 56/2.2 | 203/8.0 | 86/3.4 | 61/2.4 | 0° | 30° | 90° |

| A-8 | 38/1.5 | 64/2.5 | 239/9.4 | 102/4.0 | 38/1.5 | 6° | 30° | 120° |

| A-9 | 38/1.5 | 64/2.5 | 203/8.0 | 89/3.5 | 61/2.4 | 0° | 30° | 90° |

| A-10 | 51/2.0 | 64/2.5 | 191/7.5 | 81/3.2 | B/0.3 | 0° | 30° | 90° |

| A-11 | 51/2.0 | 64/2.5 | 292/11.5 | 102/4.0 | 127/5.0 | 0° | 30° | 90° |

| A-12 | 51/2.0 | 76/3.0 | 356/14.0 | 122/4.8 | 152/6.0 | 0° | 30° | 90° |

| A-13 | 51/2.0 | 89/3.5 | 419/16.5 | 135/5.3 | 178/7.0 | 0° | 30° | 90° |

| A-14 | 51.64/2.0.2.5 | 76/3.0 | 330/13.0 | 140/5.5 | 64/2.5 | 8° | 30° | 120° |

| A-15 | 64.76/2.5.3.0 | 89/3.5 | 330/13.0 | 127/5.0 | 64/2.5 | 8° | 30° | 120° |

| A-16 | 64.76/2.5.3.0 | 102/4.0 | 330/13.0 | 140/5.5 | 64/2.5 | 8° | 30° | 120° |

| A-17 | 76/3.0 | 102/4.0 | 483/19.0 | 168/6.6 | 203/8.0 | 0° | 30° | 90° |

BPP: 140 μm (μm/m)

| Cuid UIMH. | WD | H | T | CD | OR | α | Θ | CA |

| B-1 | 22/0.9 | 33/1.3 | 140/5.5 | 64/2.5 | 20/0.8 | 8° | 30° | 120° |

| B-2 | 25/1.0 | 38/1.5 | 165/6.5 | 74/2.9 | 25/1.0 | 8° | 30° | 120° |

| B-3 | 25/1.0 | 38/1.5 | 89/3.5 | 53/2.1 | B/0.3 | 0° | 30° | 90° |

| B-4 | 25/1.0 | 38/1.5 | 114/4.5 | 53/2.1 | 8/0.3 | 0° | 30° | 90° |

| B-5 | 25/1.0 | 38/1.5 | 178/7.0 | 64/2.5 | 76/3.0 | 0° | 30° | 90° |

| B-6 | 25/1.0 | 38/1.5 | 203/8.0 | 53/2.1 | 89/3.5 | 0° | 30° | 90° |

| B-7 | 25/1.0 | 43/1.7 | 165/6.5 | 74/2.9 | 25/1.0 | 8° | 30° | 120° |

| B-8 | 25/1.0 | 43/1.7 | 203/8.0 | 53/2.1 | 89/3.5 | 0° | 30° | 90° |

| B-9 | 25.30/1.0.1.2 | 43/1.7 | 229/9.0 | 74/2.9 | 30/1.2 | 8° | 30° | 120° |

| B-10 | 25.30/1.0.1.2 | 43/1.7 | 152/6.0 | 59/2.3 | B/0.3 | 8° | 30° | 120° |

| B-11 | 25.30/1.0.1.2 | 43/1.7 | 203/8.0 | 74/2.9 | 89/3.5 | 0° | 30° | 90° |

| B-12 | 25.30/1.0.1.2 | 46/1.8 | 229/9.0 | 74/2.9 | 38/1.5 | 8° | 30° | 120° |

| B-13 | 30/1.2 | 46/1.8 | 203/8.0 | 76/3.0 | 89/3.5 | 0° | 30° | 90° |

BPP: 100 μm(μm/míle)

| Cuid UIMH. | WD | H | T | CD | OR | α | Θ | CA |

| C-1 | 25/1.0 | 38/1.5 | 130/5.1 | 53/2.1 | 30/1.2 | 11 | 30° | 90° |

| C-2 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 11 | 30° | 90° |

| C-3 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 8′ | 30° | 90° |

| C-4 | 30/1.2 | 38/1.5 | 130/5.1 | 56/2.2 | 30/1.2 | 4′ | 30° | 90° |

| C-5 | 30/1.2 | 41/1.6 | 130/5.1 | 59/2.3 | 30/1.2 | 11 | 30° | 90° |

BPP: 90 μm(μm/míle)

| Cuid UIMH. | WD | H | T | CD | OR | α | Θ | CA |

| D-1 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 11° | 30° | 90° |

| D-2 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 8° | 30° | 90° |

| D-3 | 25/1.0 | 33/1.3 | 109/4.3 | 51/2.0 | 13/0.5 | 4° | 30° | 90° |

| D-4 | 25/1.0 | 35/1.4 | 109/4.3 | 51/2.0 | 20/0.8 | 11° | 30° | 90° |

| D-5 | 30/1.2 | 38/1.5 | 109/4.3 | 51/2.0 | 20/0.8 | 11° | 30° | 90° |

| D-6 | 30/1.2 | 38/1.5 | 109/4.3 | 53/2.1 | 1310.5 | 8° | 30° | 90° |

| D-7 | 30/1.2 | 38/1.5 | 109/4.3 | 53/2.1 | 13/0.5 | 4° | 30° | 90° |

BPP: 80 m(μm/míle)

| Cuid UIMH. | WD | H | T | CD | OR | α | Θ | CA |

| E-1 | 25/1.0 | 33/1.3 | 99/3.9 | 48/1.9 | 13/0.5 | 4° | 30° | 90° |

| E-2 | 25/1.0 | 33/1.3 | 99/3.9 | 4B/1.9 | 13/0.5 | 8° | 30° | 90° |

| E-3 | 25/1.0 | 33/1.3 | 99/3.9 | 48/1.9 | 13/0.5 | 11° | 30° | 90° |

| E-4 | 25/1.0 | 35/1.4 | 99/3.9 | 46/1.8 | 13/0.5 | 11° | 30° | 90° |

| E-5 | 30/1.2 | 38/1.5 | 99/3.9 | 51/2.0 | 13/0.5 | 4° | 30° | 90° |

| E-6 | 30/1.2 | 3B/1.5 | 99/3.9 | 51/2.0 | 13/0.5 | 8° | 30° | 90° |

BPP: 70 m(μm/míle)

| Cuid UIMH. | WD | H | T | CD | OR | α | Φ | CA |

| F-1 | 25/1.0 | 30/1.2 | 91/3.6 | 43/1.7 | 10/0.4 | 8° | 30° | 90° |

| F-2 | 25/1.0 | 30/1.2 | 91/3.6 | 43/1.7 | 10/0.4 | 4° | 30′ | 90° |

| F-3 | 25/1.0 | 33/1.3 | 91/3.6 | 43/1.7 | 13/0.5 | 11° | 30′ | 90° |

BPP: 60 m(μm/míle)

| Cuid UIMH. | WD | H | T | CD | OR | α | Φ | CA |

| G-1 | 23/0.9 | 28/1.1 | 81/3.2 | 35/1.4 | 13/0.5 | 11° | 30° | 90° |

| G-2 | 25/1.0 | 30/1.2 | 81/3.2 | 35/1.4 | 13/0.5 | 11° | 30° | 90° |